Infographic text included for screen readers

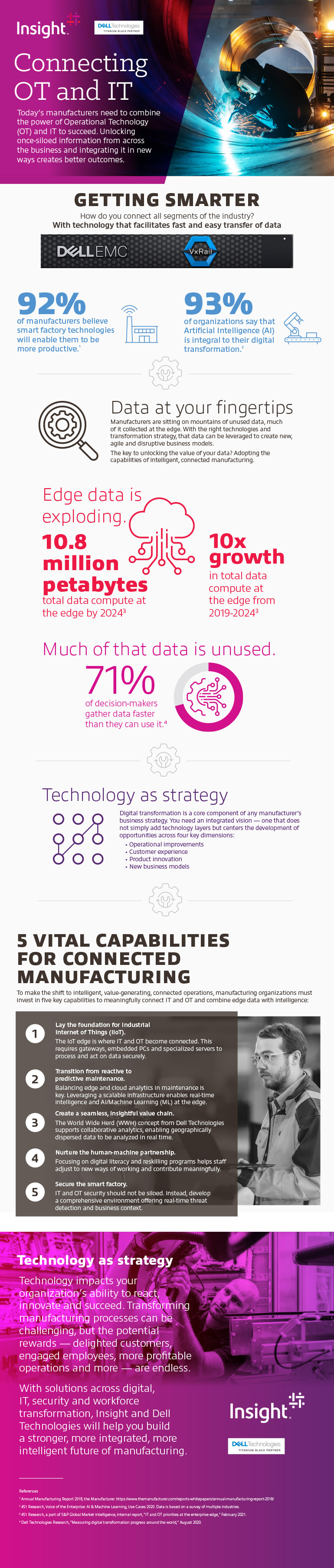

Today’s manufacturers need to combine the power of operational technology (OT) and IT to succeed. Unlocking once-siloed information from across the business and integrating it in new ways creates better outcomes.

Getting smarter

92% of manufacturers believe smart factory technologies will enable them to be more productive.¹

93% of organizations say that Artificial Intelligence (AI) is integral to their digital transformation.²

Data at your fingertips

Manufacturers are sitting on mountains of unused data, much of it collected at the edge. With the right technologies and transformation strategy, that data can be leveraged to create new, agile and disruptive business models.

The key to unlocking the value of your data? Adopting the capabilities of intelligent, connected manufacturing.

Edge data is exploding.

10.8 million petabytes total data compute at the edge by 2024³

10x growth in total data compute at the edge from 2019-2024³

Much of that data is unused.

71% of decision-makers gather data faster than they can use it.⁴

Technology as strategy

Digital transformation is a core component of any manufacturer’s business strategy. You need an integrated vision — one that does not simply add technology layers but centers the development of opportunities across four key dimensions:

- Operational improvements

- Customer experience

- Product innovation

- New business models

5 vital capabilities for connected manufacturing

To make the shift to intelligent, value-generating, connected operations, manufacturing organizations must invest in five key capabilities to meaningfully connect IT and OT and combine edge data with intelligence:

1. Lay the foundation for Industrial Internet of Things (IIoT).

The IoT edge is where IT and OT become connected. This requires gateways, embedded PCs and specialized servers to process and act on data securely.

2. Transition from reactive to predictive maintenance.

Balancing edge and cloud analytics in maintenance is key. Leveraging a scalable infrastructure enables real-time intelligence and AI/Machine Learning (ML) at the edge.

3. Create a seamless, insightful value chain.

The World Wide Herd (WWH) concept from Dell Technologies supports collaborative analytics, enabling geographically dispersed data to be analyzed in real time.

4. Nurture the human-machine partnership.

Focusing on digital literacy and reskilling programs helps staff adjust to new ways of working and contribute meaningfully.

5. Secure the smart factory.

IT and OT security should not be siloed. Instead, develop a comprehensive environment offering real-time threat detection and business context.

Connected manufacturing with Dell Technologies

Technology impacts your organization’s ability to react, innovate and succeed. Transforming manufacturing processes can be challenging, but the potential rewards — delighted customers, engaged employees, more profitable operations and more — are endless.

With solutions across digital, IT, security and workforce transformation, Insight and Dell Technologies will help you build a stronger, more integrated, more intelligent future of manufacturing.

Sources:

Annual Manufacturing Report 2018, the Manufacturer. https://www.themanufacturer.com/reports-whitepapers/annual-manufacturing-report-2018/

451 Research, Voice of the Enterprise: AI & Machine Learning, Use Cases 2020. Data is based on a survey of multiple industries.

451 Research, a part of S&P Global Market Intelligence, internal report, “IT and OT priorities at the enterprise edge,” February 2021.

Dell Technologies Research, “Measuring digital transformation progress around the world,” August 2020.